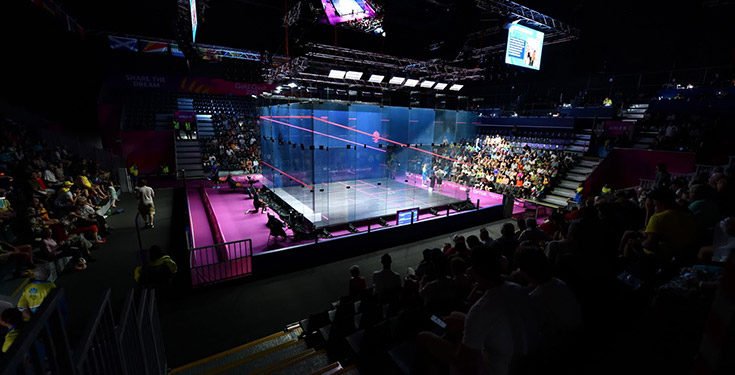

There is of course large differences between the different models and court builders out there. The overall performance of the show glass court depends on several factors that influence the optical appearance of the court and its playability. It is the prime objective to achieve great playability and great visibility live and on TV. Below specification defines the requirements of a modern show glass court.

To give an overview of the specification a new, modern glass court must have following is recommended:

Type of glass court

Professional 4-sided glass squash court (back wall door or side wall doors). Usable for singles events according to WSF standards.

Accreditation

The court is accredited by the World Squash Federation (WSF).

Tin

The tin must be height-adjustable from 19 inch to 17 inch.

TV Broadcasting and Spectator Viewing Optimisation

The glass squash court must not have any external metal structures. This is to allow spectators from the seating along the side walls a good view into the court. The court must have the option to install a light spill cover system on to of the glass, which prevents light spill over the glass.

Unrestrained view into the court from the back where cameras will be placed at high positions. No metal structure is allowed for the fixation of lights above the back wall as this disturbs the camara view.

Dark colours are used for the wall and the floor in order to provide maximum contrast for the ball (a white ball will be used). The colour of the walls and the floor are essential in their effect on ball visibility when broadcasting.

Conditions for the Players

The floor should be water and sweat absorbent. The lighting must not blind the player on high balls (the lighting structure should be designed to light against the walls to reflect back onto the field of play)

Flooring

Hard, smooth, has limited spring and provides firm footing in normal play. Capable of absorbing small amounts of moisture without becoming slippery or if provided with an impervious surface, be tested in accordance with appropriate standards to demonstrate adequate slip resistance in wet conditions. (In the absence of any National Standards, the requirements of the German DIN 18032 Part 2 when tested in wet conditions, is considered acceptable). The bounce of the ball shall be of even height and pace over the whole area of the floor, and when viewed from vertically above the line of flight of the ball, the linear path of the ball shall not be affected when it bounces on the floor.

The floor shall be of dark colour, preferably black and have a matt finish. Shiny or reflective surfaces cannot be accepted. The court floor construction and the metal frame should be prepared to allow an upgrade of a glass floor to be used.

Walls

Walls to be as per court manufacturer’s specification which meets WSF specification.

The average reflectance of the front & side walls shall not be less than 50% at any point in a clean condition. The reflectance of the front & side walls shall not vary at any point by more than plus or minus 5% of the average reflectance.

The court walls shall be vertical to within plus or minus 5mm in a height of 2 meters when measured

(i) within 250mm of each corner of the court

(ii) at 3 additional intermediate points evenly spaced along the length of each wall. The walls of the court shall be straight to within plus or minus 15mm in the length of any wall when measured horizontally at a height of 1 metre above finished floor level. The walls of the court shall be plane and:

(i) have no indentations, holes or open joints of more than 2mm across in any dimension in the plane of the wall

(ii) have no variations from the true surface of more than 3mm when measured in any direction with an 1800mm long straight edge.

The walls should be raised up to 5.1m on the front and side walls: a) to stop balls going out of court too often, b) to give advertising spaces above the out line.

The fittings holding individual glass plates together should be manufactured from a durable material i.e. steel or aluminium and not from plastic or polymer. The fittings should also be painted black or in the colour of the wall to not be visible in the TV image.

The walls should be designed of only two glass plates in height to allow for fast installation.

The glass should be coloured by ceramic paint and not foils as the court will be portable and applied foils will get damaged over time.

The courts door is normally positioned in the middle of the back wall. There is a 2nd variantion: the glass court with two doors – one at each side wall. In this cas back wall does not contain a door, to give better TV visibility from the back (main camera view).

Light

The lighting is to be part of the glass court and permanently attached to the court. The lightsystem has to be attached to the glass with special fixings and light beams – no extra metal posts shall carry the light system.

The minimum light requirements is 1400 lux (at floor level) at any place within the court. LED light shall be used, which suitable for super slow motion up to 4000 fps.

The LED lights must also have the ability to run a programmed lightshow.

Marking lines

Beside the traditional lines (with tape), an option to use LED marking lines with a wireless remote control shall be part of the court. The LED marking lines must be able to display any RGB colour permanently and even on all lines.

Court assembly

The court must be installed within a 3-5 day period.

The court must be demounted completely within 2 days

The court must be supplied with all plans and documentation for the assembly of the court.

The court must be transportable and allow for reassembly in another location without any further expense but the labour and tools for a regular build up.

Previous post

Previous post